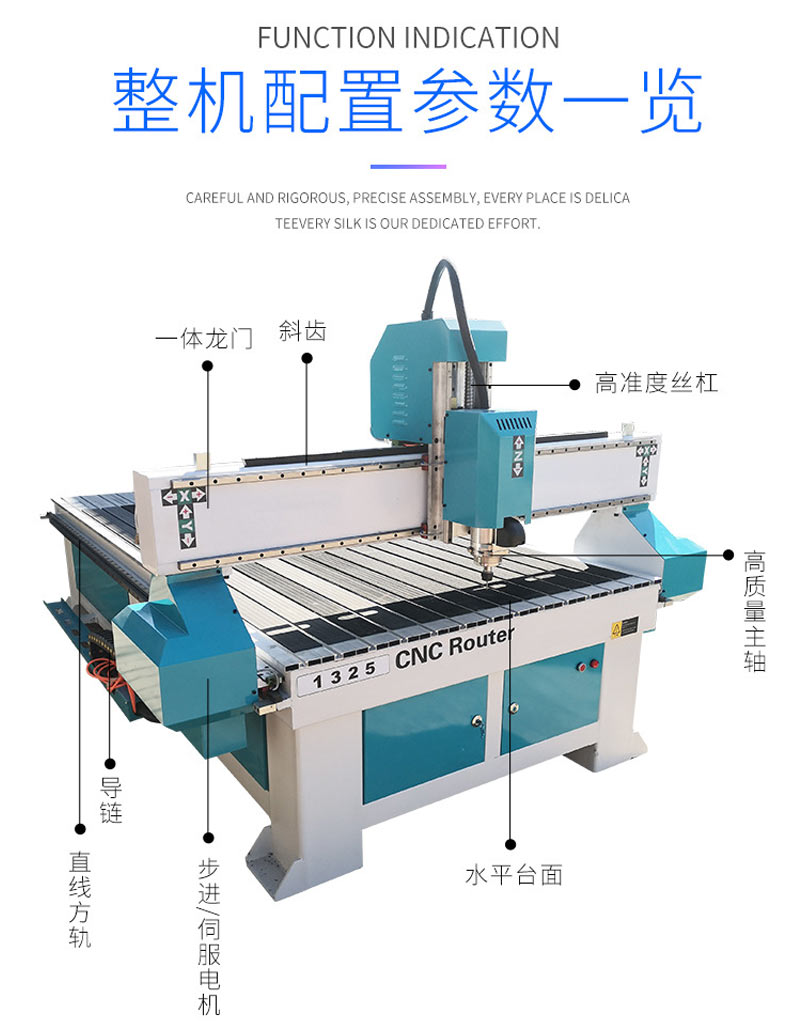

SW1525-2T Double Head Woodworking Carving Machine

| Serial number | describe | parameter |

| one | XTheY. Z-axis travel | 1500*2500*320mm |

| two | Platform size | 1600*2900mm |

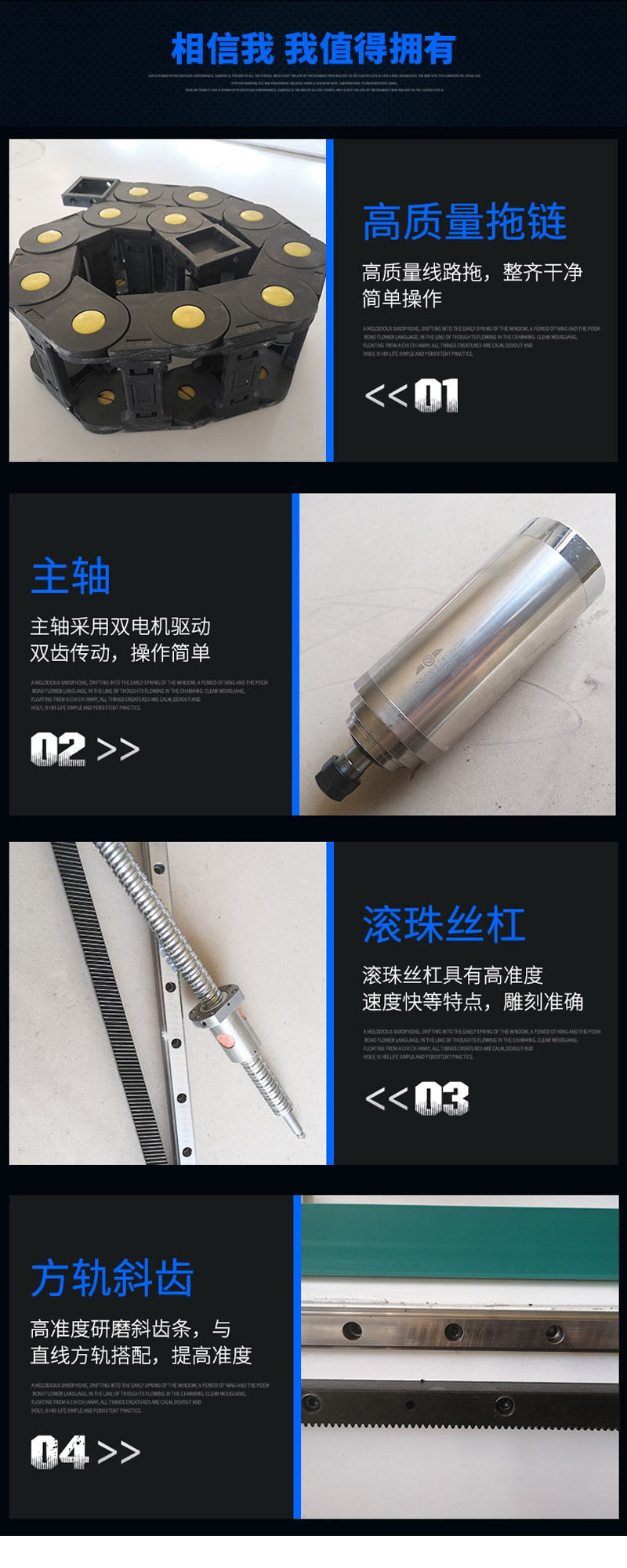

| three | Maximum operating speed | 35m/min |

| four | Maximum carving speed | 25m/min |

| five | resolving power | 0.01mm |

| six | Repetitive positioning accuracy | < 0.05mm |

| seven | Repetitive positioning accuracy | DSP/Main frequency 100MHz |

| eight | Carving instructions | G code *. u00 *. mmg *. plt |

| nine | Software operating environment | win98/2000/xp |

| ten | working voltage | AC380V/50Hz |

| eleven | Spindle power | 3KW |

| twelve | Spindle speed | 0--24000r/min |

| thirteen | operation mode | Step by Step |

1. Dual spindle carving: Dual spindle can work simultaneously on the same pattern, greatly improving the processing speed of the board and the efficiency of completing the work of two devices in the same time. In some cases where the processing volume is not large, single spindle independent work can also be achieved, effectively and reasonably controlling production costs.

2. During batch processing, the product has good consistency and high quality.

2. During batch processing, the product has good consistency and high quality.

3. The overall steel structure is welded and tempered with aging treatment, which is sturdy and does not deform. Longmen style mobile, fixed workbench, can process materials on the workbench freely.

4. The Y-axis of the machine tool adopts rack and pinion dual drive, which can perform heavy cutting. To suit professional production, the Z-axis is raised to 320 for easy feeding.

5. Adopting an embedded DSP numerical control system, it can achieve breakpoint carving, power-off memory function, and complete offline operation.

6. Compatible with G machining codes generated by various CAD/CAM design software such as Type3/Artcam/Jingdiao/Wentai.

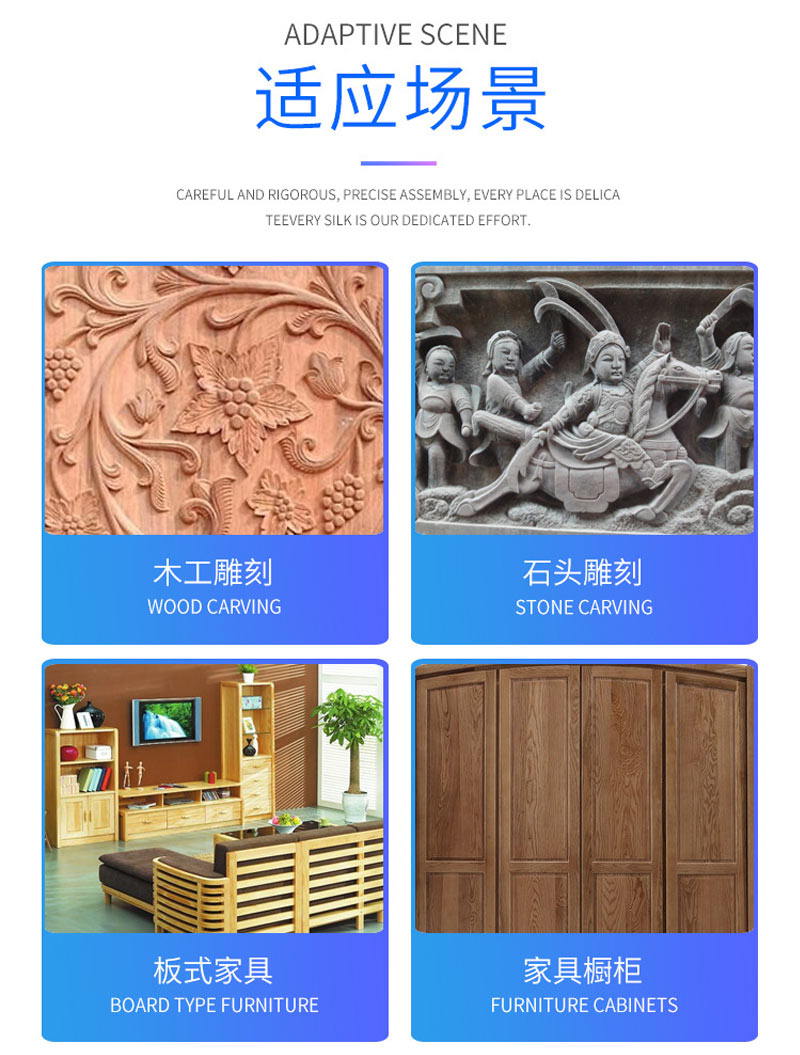

Specially designed for customers who require large-scale and small workpiece processing, suitable for processing cabinet doors, craft gifts, relief crafts, non-ferrous metal carving and cutting, and many other industry products.

Monthly production of over 1000 units.

Our professional sales and after-sales service team will promptly and efficiently solve your problems.

| National Unified Sales Hotline: 400-6587-688 |

| Jinan Huawei CNC Equipment Co., Ltd |

| Address: No. 18-1 Tonghua Road, Jinan City, Shandong Province Postal Code: 250000 Phone: 0531-88620266 Fax: 0531-88276988 Mobile phone: 15853195586 E-mail: cncmachine@jnhwcnc.com |

Related products: